ABSTRACT

Project summary

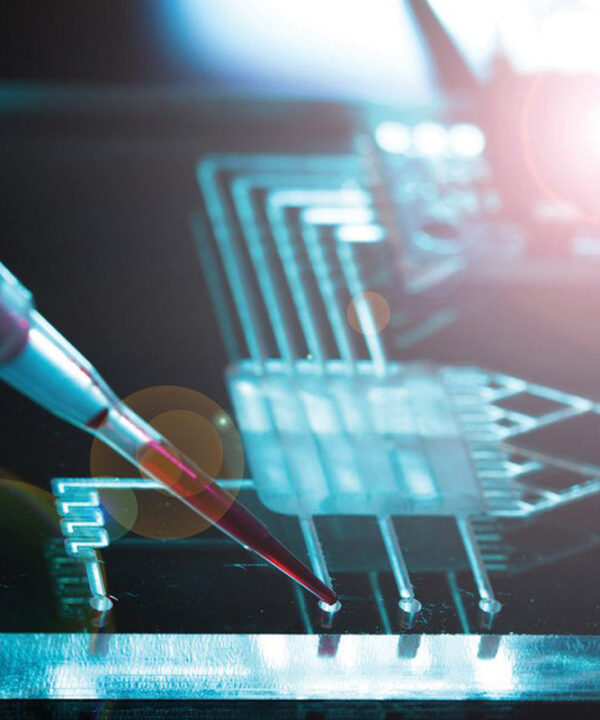

In order to develop a device for in-process monitoring of cultures of engineered T cells, TITAN will design and produce a miniaturized and disposable multifunctional microfluidic sensor cartridge (LoC) to be connected to the bioreactor. The LoC format follows from the need to minimize both the amount of sample required for testing (most of the culture being preserved for reinfusion into the patient) and the cost of reagents, whilst providing a robust, user-friendly device. The LoC will integrate a number of different units of either of two different types, the first for cell-based assays (cell count, immunophenotyping, target cell killing), the second for solution-based assays (concentration of metabolites and cytokines).

Standard Critical Quality Attributes to be monitored are:

- total viable cell count;

- glucose and lactate/pyruvate concentration in the culture medium

- cell purity and identity, measured from the fraction of cells expressing the synthetic receptor;

- expression of CD4/CD8 coreceptors;

- cytokine production (IL-2, IFNγ, TNFα, GM-CSF e MIP-1α);

- cell cytotoxic potency on the autologous patient tumour or artificial targets.

The technological process will consist of:

- fabrication of the microfluidic circuit based on numerical simulations and rapid prototyping by laser machining;

- fabrication of the sensing component based on functionalized microelectronic transducers (miniaturized electrode arrays, FET);

- sealing/bonding of the microfluidic and sensing chips by novel microwelding techniques for joining heterogeneous materials. The integrated LoC will be electrically interfaced to an external control unit controlled by ad hoc software for data display and recording.

In addition to standard Critical Quality Attributes, TITAN will also undertake discovery of novel process indicators for the expansion of engineered T-cells by genome-wide analysis. If successful, detection modules for these markers will be implemented on the LoC.

Finally, TITAN will also address T cell transduction by:

- comparing the major classes of synthetic nanovectors for their transduction efficiency in primary T cells;

- manipulating of the NP protein corona;

- investigating the use of NPs for combined T cell activation and transduction;

- exploring the use of minivectors, to asbolish the risks of insertional mutagenesis.

Research Together to Innovate

Research Together to Innovate

Immunotherapy with genetically engineered T cells has achieved some spectacular success in clinical trials and has obtained initial marketing approval by the FDA in the USA. However, whilst it is likely to be extended to several other common tumour types and even chronic disease (atherosclerosis, diabetes etc.), it is currently very expensive. This is partly due to the fact that, being a highly personalised therapy, it is only effective in the donor patient, hence economies of scale cannot be achieved.

On the other hand, mass production is not required: less than half a billion cells are needed in a single dose. A key need is the widespread availability of small-scale bioreactors. However, production conditions are likely to remain difficult to standardize, given the high heterogeneity of the starting material, which depends on an individual’s constitutional factors and clinical state, and the inherently complex and still only partially understood nature of T cell activation and expansion. Currently available small-scale bioreactors do not provide in-process monitoring. TITAN aims to fill this crucial gap, introducing an incremental innovation step. By allowing continuous sampling of critical quality attributes, deviations from the desired range may be quickly recognised and appropriate corrective actions of process parameters may be promptly taken, guaranteeing an optimal outcome. It may be envisaged that, in the next step, these corrective actions will

be easily automated to realise a complete Process Analytical Technology (PAT) unit.

To achieve its aims, TITAN will develop sophisticated tools for the hydrodynamic modelling of cells in complex microfluidic networks and for the accurate and efficient manufacturing of hybrid polymeric/semiconductor devices for medical applications. A major innovative aspect will be the integration of both sample preparation and of the different analytical modules into a fully automated platform that can be conveniently accessed by end users. This is expected to establish a paradigm for a whole host of next generation LoCs.

A second TITAN aim is the development of efficient strategies for non-viral transduction of synthetic receptors into primary T cells. Current methods rely on retro- or lentiviral vectors, which are efficient, but relatively costly and laborious to prepare for mass production purposes. Moreover, despite the incorporation of several safety mechanisms, they are not entirely free from residual risks (shedding, mobilization, germline transmission, immunogenicity, and insertional mutagenesis).

TITAN will develop cheaper and efficient synthetic nanovectors in combination with minigenes that do not require chromosomal integration, hence abolishing the risks of insertional mutagenesis.

TITAN’s overarching aim may thus be summarised as a major contribution to make a highly successful radical new treatment for cancer (immunotherapy with engineered T cells) safer, more efficient, cheaper and more easily available at widespread locations. This will clearly benefit in primis cancer patients and their families, and make the treatment sustainable by health care system. From a commercial perspective,

TITAN proposes a significant innovation in a market poised to grow exponentially in the upcoming years.

Considering the prevalence of cancer, the potential market of cell products for immunotherapy based on

engineered T cells is in excess of several billion EUR in the EU alone. Developing technology to produce

the cells in a cheaper, safer and more efficient way offers substantial entrepreneurial opportunities, which

TITAN is determined to sieze in order to contribute to the creation of new jobs and to economic growth in

Southern Italy.

TITAN’s activities and aims are entirely consistent with the priorities set by European and Italian strategic agendas for innovation-led sustainable growth.

A major pillar of Horizon 2020 conisists of Priority 3 “Societal Challenges”, chief amongst which is the “Health, demographic change and wellbeing” sector. Amongst the most prominent challenges, the corresponding work programme identifies “the rising and potentially unsustainable health and care costs, mainly due to the increasing prevalence of chronic diseases”. It also lists two of the major Objectives and

policy drivers as “the effective integration of personalised medicine approaches into healthcare services and systems to the benefit of patients and citizens” and “innovation in the European healthcare domain and industry by the application of advanced technologies” (Horizon 2020 Work Programme 2018-2020).

Accordingly, special emphasis is placed on the development of novel medical technologies and advanced therapies that aim to translate new knowledge into innovative applications and accelerate their large-scale uptake and deployment in different settings, making health and care systems and services more accessible, responsive and efficient. A particular focus is on:

- Personalised Medicine,

- innovative health and care industry, and

- advanced therapies based on gene, cell or tissue-engineered products in order to prevent/treat diseases and conditions affecting large patient groups. The EU Third Health Programme 2014-2020 has also echoed amongst its priorities the sustainability of health systems and an increase in the prevalence of chronic disease, and indicated innovative, efficient and sustainable health systems as a specific objective.

TITAN will develop products for an Advanced Cell Therapy (engineered T cells for immunotherapy) that is uniquely personalised (being based on the patient’s autologous cells) and is targeted to cancer, currently a major health threat. Whilst it is reasonable to expect that immunotherapy with engineered T cells, which was initially validated in leukaemias, will also prove applicable to common solid tumours, initial marketing has set a very high price for it, which raises questions as to both its widespread availability and its sustainability by health care systems. TITAN aims to develop technologies to reduce these costs, whilst making the manufacturing process both more efficient and safer.

TITAN’s partners are leading science and technology players within at least two of the twelve areas identified by the PNR 2015 – 2020 and by the National Strategy for Intelligent Specialization, which they substantially contributed to define: Health, in particular innovative/advanced devices and technologies for the treatment of chronic disease, and Smart Manufacturing, in particular advanced sensors and microsystems, new systems and technologies for micro- and nanomanufacturing, technologies for the manufacturing of personalised products. TITAN’s partners are actively engaged in the development and application of Key Enabling Technologies of major European interest: micro- and nanoelectronics, nanotechnology, industrial biotechnology, advanced materials and advanced manufacturing technologies.

TITAN is largely the brainchild of the Joint Research Center established at Lecce over the past few years by CNR Nanotec and two large enterprises, Ospedale S.Raffaele and STMicroelectronics. Here a cross-disciplinary research group has been built from researchers with widely different backgrounds and skills, from clinical neuroscientists and immunologists through to biotechnologists, chemists, physicists and engineers, to work in physical as well as thematic proximity on developing translational applications of basic research to medicine. In order further to validate its translational approach, the Center has recently established close connections with major regional referral hospitals in Regione Puglia: the IRCSS Istituto Tumori Giovanni Paolo, Bari and the Center for Clinical Research on Neurodegenerative Disease, a joint venture between Policlinico Bari and Ospedale Panico, Tricase. Thus in embryonic form the Joint Research Center replicates an entire value chain, from the clinicians who confront real patients to the biotechnologists that discover a novel treatment, the anotechnologists that design the tools to implement it, the industrial manufacturer that makes it widely available, and finally back again to the clinicians who validate it. This is precisely the paradigm that the National Strategy for Intelligent Specialization aims to foster in order to generate competitive advantages for our economy and improve the conditions of our fellow citizens, and that TITAN intends vigorously to pursue and expand.

Tumour immunotherapy has seen a dramatic resurgence of interest over the past 15 years, partly due the development of genetically engineered T cells. Spectacular success has been achieved in some acute leukaemias with T cells engineered to express a chimaeric receptor against CD19. This has recently become the first T-cell therapy to be approved in the USA and is now commercially available. However, it

has a price tag of USD 475,000.

Whilst leukaemias are relatively rare, engineered lymphocytes are being developed for several other tumours, and may conceivably be applied to other chronic disease. Not surprisingly, this has led to a huge surge of interest both from patients/doctors and from the biotech/pharma industry.

Engineered T-cells are an epitome of personalized medicine, since they are customized for each patient. The process involves 4 main steps:

- the extraction of T-cells from the patient;

- activation and transduction;

- expansion over an approximately 2-week period;

- formulation and reinfusion into the patient.

TITAN aims to provide tools to improve two key steps: a.) gene transfer into the T cell and b.) the subsequent ex-vivo expansion. As for the first, current viral vectors are efficient, but relatively costly and laborious to prepare for mass production. Moreover, they are not entirely free from residual risks. Cheaper and even safer transduction tools would be preferable, and this is addressed in OR6 of TITAN.

As for the expansion phase, the process requires cGMP standards, which are expensive to implement and maintain, and is considerably challenging because of: a.) the great variability of the cell source, ie single

individuals with a host of constitutional and disease-related differences; and b.) the intrinsic heterogeneity and complexity of the product, which, even after engineering, contains multiple cell types and functional classes. This threatens commercial viability. As each autologous T cell product is made from one patient, there are no substantial economies of scale. Moreover the dosing is relatively limited, hence negating the rationale for large bioreactors as used for classical biologics. In contrast, high-throughput manufacturing for this application requires the parallel operation of small-scale plants.

A “point-of-care” manufacturing model has emerged whereby the cells are produced at specialist treatment centres. This is favoured by many academics, hospitals, patients and policy makers, as, quite apart from some technical advantages, it may be pursued at reduced costs. Point-of-care manufacturing, however, ideally calls for sealed, fully automated, user-friendly devices. A number of tools/equipment have been introduced for the small scale manufacturing of cell products. However, besides monitoring some basic parameters, none of the available systems enables in-process monitoring of quality attributes that are essential in the final product.

This need is addressed in OR1 to OR4 of the current proposal. A miniaturized and disposable device (LoC) will be designed and fabricated, since it will minimise both the amount of sample to be tested, hence preserving most of the culture for reinfusion, and the analytical reagents, hence reducing costs. Whilst our initial prototype will be based on a minimal number of critical quality attributes, its intrinsic modularity and scalability will make it easy to expand to many more. By allowing continuous sampling of critical quality attributes, and their correlation with raw materials and process parameters, our LoC will become a key element for the application of Quality-By-Design principles to the manufacturing of T cells for immunotherapy, as advocated by regulatory bodies. We anticipate that the LoC produced as a result of TITAN will become the initial building block of a complete Process Analytical Technology unit, able to both sense deviations in critical quality attributes and promptly react by adjusting process parameters.

Cancer immunotherapy was elected Breakthrough of the year 2013 by the prestigious journal Science, andthere may no doubt as to its innovative and transformative nature from both a fundamental and a clinicalviewpoint. The great potential of engineered T cells for adoptive cell immunotherapy is testified by thenumber of start-up companies that have sprung-up in the field (eg Kite, Juno, Bluebird Bio, Adaptimmune,Cellectis and Celyad) and that, besides raising impressive amounts of capital on private and publicplacements, have been signed on for major deals by established big pharma players.

There are however atleast two major issues facing the field. The first is whether it can be applied to common solid tumours, thesecond, which concerns the current proposal, whether it can be made widely available at reasonable costs.High costs are due in part to the fact that, in their current form, engineered T cells are a unique example ofpersonalised therapy that, being based on autologous cells, is only effective in the donor patient, henceeconomies of scale cannot be achieved.

On the other hand, mass production is not required: less than halfa billion cells are needed, in principle in a single dose that does not need repeating. The key elementneeded is therefore the widespread availability of small-scale bioreactors. However, the productionconditions are likely to remain difficult to standardize, given the high heterogeneity of the starting material,which depends on an individual’s constitutional factors and clinical state, and the inherently complex andstill only partially understood nature of T cell activation and expansion. This is why in-process monitoringwill need to be implemented in addition to quality controls at the end. Currently available apparatus donot provide this function.

TITAN aims to fill this crucial gap, introducing a key innovation step. Byallowing continuous sampling of critical quality attributes, deviations from the desired range may bequickly recognised and appropriate corrective actions of process parameters may be promptly taken,guaranteeing an optimal outcome. It may be envisaged that, in the next step, these corrective actions willbe easily automated to realise a complete Process Analytical Technology (PAT) unit.Quite apart from the intrinsic originality and novelty of its objectives, TITAN will make use of sophisticatedstate of the art technologies, in particular tools for the hydrodynamic modelling of cells in complexmicrofluidic networks and for the accurate and efficient manufacturing of hybrid polymeric/semiconductordevices for medical applications.

A major innovative aspect will be the integration of both samplepreparation and of the different analytical modules into a fully automated platform that can beconveniently accessed by end users. This is expected to establish a paradigm for a whole host of nextgeneration LoCs, which will require minute amounts of easily collected samples to be processed in a fullyautomated way. Most current LoCs however still lack the first vital stage of initial sample preparation.Another key step addressed by the current proposal is the development of efficient strategies for non-viraltransduction of synthetic receptors into primary T cells. Whilst several approaches are in principleavailable, rigorous comparisons have not so far been performed in primary T cells.

Perhaps the most original aspect of the proposed approach is the exploitation of the protein corona to optimize transduction.An additional innovation will be the use of synthetic nanovectors in combination with minigenes that do notrequire chromosomal integration, hence abolishing the risks of insertional mutagenesis.

The partnership has been carefully constructed. At its core are:

- a prestigious private academicorganization and major healthcare provider (OSR);

- a large multinational company(STMicroelectronics) that is a world leader in the area of microelectronics, with an expanding portfolio ofinterests in medical devices;

- CNR, perhaps the most far-reaching Italian public ResearchOrganization, represented in TITAN by nine separate Institutes belonging to four different Departments,which underlines the breadth of the interdisciplinary research effort invested;

- La Sapienza, Roma, one of the top-ranking Italian Universities. Within this partnership, OSR and two CNR Institutes (IFT and IBP)provide the essential expertise on synthetic receptors and T cell transduction, of which they areinternationally recognised leaders; another two CNR Institutes (ITB and IBIOM) with substantial trackrecords in the omic sicences will perform novel marker discovery, whereas CNR-Nanotec, IFN, ITIA, IPCBand IPCF, La Sapienza and Politecnico Bari will develop all technological aspects in partnership withSTMicroelectronics.

The Research Institutes have an impressive record of achievements in device designand microfabrication, synthesis of nanostructured materials and their characterization. The partnership iscompleted by two PMI that will be involved in application development. Project coordination will beundertaken by CNR Nanotec, Lecce, which in its short life has managed to establish for itself a strongreputation as an international center of excellence in the emerging field of the Nanosciences. It must beremarked that CNR Nanotec, OSR and ST have already established formal cooperation agreements thathave led to the constitution in 2016 of a Joint Research Center at Lecce, where staff from all 3 Institutionswork side by side. A collaboration agreement has also been signed by CNR Nanotec with ICRSS IstitutoTumori Giovanni Paolo II, Bari and the Center for Clinical Research on Neurodegenerative Disease,Tricase (Lecce).

TITAN will make a major contribution to the Health area, by making immunotherapy with engineered Tcells more widely available. It will thus benefit in primis cancer patients. Immunotherapy not onlyprovides a radical cure, but also avoids the often devastating side-effects of traditional approaches(chemotherapy, radiotherapy, surgery).

Having the “magic bullet”, however, is not of much use if it is notaffordable. The high price at which the first CAR-T cell product has been marketed implies a financialburden on healthcare systems greatly exceeding available resources. There is therefore an urgent need toreduce costs without compromising quality and safety. TITAN will contribute important elements to thisend. The integrated LoC to be designed and prototyped will enable real-time monitoring and adjustment ofprocess parameters, guaranteeing an optimal end product and making the small-scale bioreactor strategyboth efficient and ultimately more user-friendly.

Crucially, in-process monitoring capability is lacking insmall-scale bioreactors currently in use. A further contribution to cost reduction will be through thedevelopment of efficient and safer non-viral vectors for T cell engineering. Cost savings will make thetreatment more sustainable by healthcare providers.The products and processes developed by TITAN will be patented. However it is the partners’ intention togo well beyond this, and actively explore the possibility to found new companies to exploit the resultsdirectly. The start-ups will likely be based in Puglia, close to the Joint Research Center involvingCNR-Nanotec, OSR and ST. CNR-Nanotec has promoted a shared infrastructure model by which state ofthe art high-tech facilities built with heavy investments of public funds are made accessible, upon suitableagreements, to medium/small industrial players who could not otherwise afford them. Through its ownTechnology Transfer Office, CNR-Nanotec has also established promising contacts with investment fundsinterested in new technologies.The potential market for cell-based immunotherapy products is likely to show an explosive growth over thenext few years.

As reported above, a number of start-up companies have sprung-up, most of which arefocused on the engineered T cells rather than the equipment to produce them. However small-scale celltherapy manufacturing will need to integrate sophisticated process control units and minimize all costs. Thedevices and the materials for non-viral gene transduction proposed by TITAN specifically target this need,and will certainly offer substantial and entrepreneurial opportunities. Assuming an incidence of about 2,800,000 cancer per year only in the EU (data from GLOCOCAN 2012, http://globocan.iarc.fr), of which 50% suitable for immunotherapy with engineered T cells, the market for the products developed by TITANmay easily reach a value in excess of 500 MEu/year. The endorsement by a large worldwidemicroelectronics manufacturer (ST) and an internationally renowned academic center/healthcare provide(OSR) is sure to provide a powerful boost for TITAN-branded products. On a wider perspective, thetechnologies developed by TITAN will have other applications in the fast emerging field ofprecision/personalised medicine. ST is particularly interested in next generation LoCs for “diagnostics forthe masses”, to be made widely available at points-of-care at family doctors’, chemists, or even departmentstores. Internal ST forecasts predict that the LoC market will grow from USD 3M (2019) up to USD 10M(2021). Any LoC-related innovation achieved by TITAN will strengthen the position of ST in the sector,and may be expected to lead to an expansion of the Lecce unit, which is responsible within ST for thisapplication.

Likewise, from a healthcare provider viewpoint, OSR is interested in high tech developmentsfor Telemedicine and the Personalised Health market. The success of TITAN may be expected to lead tofurther recruitment of OSR personnel at the Joint Research Center at Lecce. Nearly 75% of the fundingrequested by TITAN (3.5 Meu) will be used for the recruitment of research personnel, to be selectedprimarily from amongst young, bright graduates and postgraduates. This would amount to up to 50 highlyqualified jobs.

If TITAN delivers on its objectives, it looks likely that these jobs will not only bemaintained, but expanded by at least an equal amount over the subsequent 5 years. The high profile of boththe public and industrial partners, the strong interest of the application (immunotherapy of cancer), and thebreadth and novelty of the technologies to be developed may be relied upon to act as powerful attractors for both bright researchers and entrepreneurs/investors.

TITAN will be an important stepping stone for more general LoC applications. The business model fordiagnostic LoCs is consumer-led: the LoC must have reduced unit costs and gain margins to make each testmore affordable and foster wider use, so that profit is made out of sale of a great number of one-shotdisposable units.

However, for the specific case of cell-based immunotherapy, producing a key technologyto cut costs would imply:

- gaining a leader position in a field with important social implications

- kindle even more interest in immunotherapy and in LoCs, with further medium-run positive feedback onthe industrial production of LoCs

- raise interest in different therapeutic applications where stand-alone LoC may be needed

- get a considerable return in terms of visibility and public consideration. Over the next 3 years STMicroelectronics plans to maintain a high level of annual R&D expenditure (about440 Meu) and of R&D expenditure to total revenues ratio (about 26%).

If the TITAN project is successful,the investment in R&D at the ST unit of Lecce, currently composed of 19 researchers, will not only bemaintained but strongly strengthened, giving the company’s Puglia branch an increasingly important rolein the sector of industrial biotechnology research.With TITAN STMicroelectronics aims to expand its knowledge basis and strengthen its position in the chainof electronic biomedical applications based on advanced technologies. TITAN proposes a generationalleap in a market poised to grow exponentially in the upcoming years.

For these reasons,STMicroelectronics is particularly excited by the opportunities offered by the project, and is confident thatits success will boost its competitiveness against the other major international players. However, the technological challenges will require an extra-effort of industrial research and development,which would be impossible without substantial public contribution – especially considering the high risksassociated with such advanced research.

As far as ST is concerned, in the absence of public funding thespecific activities addressed by TITAN would most likely be diluted over a longer timetable withsubstantially reduced resources – at most a feasibility study of a platform of semiconductor biosensors overa 4-5 year timeframe.

Funding will greatly accelerate the process, in direct proportion to deepening itssocial impact. As for the benefit of the incentives, therefore, it is important to emphasise that:

- The technological goals of TITAN are higher-ranking than those pursued by a single company duringits ordinary research activity

- The results will be produced within a short period – much shorter than is normally required for anR&D program of equivalent complexity

- The results will be a starting point for further benefits for the whole community, as well as foradditional R&D activities (by academic and industrial partners) and exploitations (industrial partners)

- STMicroelectronics has a unique and consistent strategy in the ‘healthcare’ domain, in which advancedresearch activities in enabling technologies for applications to ‘on-chip centralized’ laboratories play amajor role. Such strategy perfectly fits the goals of the present funding programme, maximising thepotential contribution of industry. Demanding applications require engineered solutions.

Ospedale San Raffaele has a long-standing collaboration with CNR Nanotec and STMicroelectronics, withwhom it shares a number of long- and medium-term objectives. One of these is the translation of the mostpromising achievements of its academic basic research activities into commercial applications that may bemade widely available to patients and doctors.

Within the OSR Division of Immunology, transplantationand infectious diseases, the Innovative Immunotherapy Unit has made some major breakthroughs in thefield of tumour immunotherapy with engineered T cells, which are currently the subject of very stronginterests by patients, doctors, biotech and pharma companies.

Since 2016, the Innovative ImmunotherapyUnit has already transferred some of its activities in this sector to a new translational research group thathas been formed at the Joint Research Center with CNR-Nanotec at Lecce.The Lecce OSR unit involved in TITAN is well-equipped for immuno-oncological, cell culture andmolecular biology studies.

Equipment available in the lab include a confocal microscope, bright field andfluorescent microscopes, a dissection microscope, a cryostat, several refrigerators, a liquid nitrogencontainer, an experimental digital electromyography system. An electron microscopy room is adjacent tothe main lab. In the joint laboratory at CNR NANOTEC, the OSR team, currently comprised of 8 medicalresearchers, works closely in an interdisciplinary environment with CNR and ST Microelectronics staff todevelop new diagnostic and therapeutic approaches based on nanotechnology.

If the TITAN project issuccessful this joint laboratory would be greatly enhanced, both in terms of research personnel andequipment, increasing its critical mass and hence its capacity for clinical translational research.In particular OSR is extremely interested and committed to developing the CAR-T technology into productsthat are more efficient, safer and more widely accessible. Considering the prevalence of cancer, areduction in the cost per treatment with engineered T cells to EUR 100.000 would make the therapy muchmore affordable, whilst still representing a potential market in excess of several billion EUR in the EUalone. OSR is determined to invest in this rapidly expanding Biotech and Personalised Medicine market,maximizing the benefits to patients, and the opportunities for economic growth and the creation of newjobs, particularly in Southern Italy.